I. Bohlokoa ba ho Khetha Ketane le Mahlaahlela a Nepahetseng

Lifekthering tsa samente, li- lifts tsa libakete li bohlokoa bakeng sa ho tsamaisa thepa e boima, e thata e kang klinka, lejoe la mokoetla le samente ho ea holimo.Lihokelo tse chitja ketane le mahlaahlelajara khatello ea kelello e kholo ea mochini, ho etsa hore moralo oa bona le taolo ea boleng ba tlhahiso e be tsa bohlokoa bakeng sa katleho ea ts'ebetso. Ke ka hona ho bohlokoa ho khetha likarolo tse nepahetseng le hore na SCIC e sebetsana le sena joang:

1. Bokhoni ba ho Jara Moroalo:Liketane le mahlaahlelae tlameha ho mamella meroalo e matla le ts'oenyeho e tsoang ho motsamao o sa khaotseng oa bakete. Likarolo tse sa tsitsang li beha kotsing ea ho se sebetse ka tšohanyetso, e lebisang ho theohe, likotsi tsa polokeho le litokiso tse bitsang chelete e ngata. Ho khomarela ha SCIC ho litekanyetso tsa DIN ho netefatsa hore lihlahisoa tsa rona li fihlela litlhoko tse hlokahalang tsa matla, joalo ka matla a boletsoeng a 280–300 N/mm².

2. Apara Resistance: Sebopeho sa abrasive sa lisebelisoa tsa samente se potlakisa ho roala ha likarolo tsa lifti. Liketane tse thatafalitsoeng ke mekotla (ho fihla ho 800 HV) le mahlaahlela (ho fihla ho 600 HV) li fana ka sebaka se tšoarellang sa ho thibela ho khoptjoa, ha li ntse li boloka ho tiea ha mantlha ho thibela ho phunyeha. Ts'ebetso e nepahetseng ea SCIC ea carburizing e fihlella botenya bo batloang ba 10% le boima ba 5-6% bo sebetsang hantle, bo netefatsang ts'ebetso ea nako e telele.

3. Tumellano ea Maemo: Ho lumellana le DIN 764, DIN 766, DIN 745, le DIN 5699 e tiisa horediketane le diketanekopana le litekanyetso tsa indasteri bakeng sa litekanyo, thepa ea thepa, le ho tšepahala. Bokhoni ba SCIC ba ho fihlela litekanyetso tsena bo netefatsa boleng bo tsitsitseng bo ikamahanyang le lits'ebetso tse boima.

4. Taolo ea Boleng ba Tlhahiso: Taolo e matla ea boleng ba SCIC-ho tloha khethong ea thepa ho ea tlhahlobong ea ho qetela-e fokotsa mefokolo le ho netefatsa ho nepahala, ho thatafala le matla. Bokhoni bona bo fokotsa menyetla ea ho hloleha tlas'a maemo a thata a lifeme tsa samente.

Ho khetha se nepahetsengdiketane le diketanee bohlokoa bakeng sa ts'ebetso le polokeho ea li-lifti tsa hau tsa libakete. Ho SCIC, lihlahisoa tsa rona li entsoe le ho etsoa ho finyella litekanyetso tse thata tsa DIN, ho etsa bonnete ba hore li ka mamella meroalo e boima le thepa e thata e tloaelehileng lifemeng tsa samente. Ka taolo ea rona e matla ea boleng, o ka tšepa hore liketane le liketane tsa rona li tla fana ka ts'ebetso e tšepahalang, ho fokotsa kotsi ea ho hloleha ho sa lebelloang le litšenyehelo tsa tlhokomelo.

II. Ho leka-lekanya boima le matla nakong ea tlhahiso

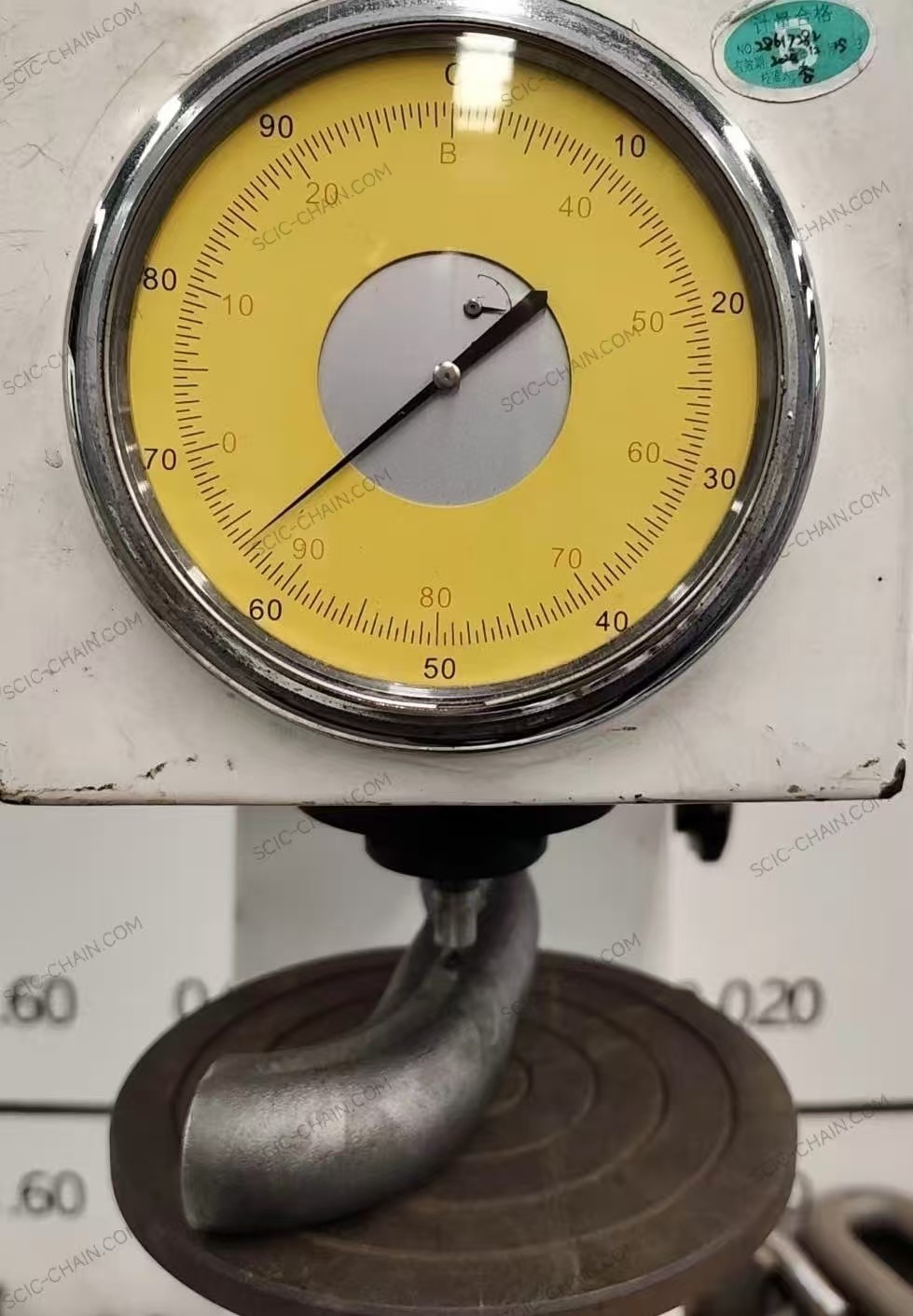

Ho fihlela boima ba bokaholimo bo boletsoeng ke moreki (800 HV bakeng sa liketane, 600 HV bakeng sa mahlaahlela), botenya ba carburizing (10% ea bophara ba khokahanyo), botebo bo sebetsang ba boima (550 HV ho 5–6% ea bophara), le matla a ho pshatla (280–300 N/mm²) ho hloka tekano e hlokolosi lipakeng tsa thata le matla. Mona ke kamoo SCIC e fihlelang sena ka khetho ea thepa, kalafo ea mocheso, le carburizing:

Mekhoa ea Bohlokoa ea Tlhahiso

1. Khetho ea Lintho:Litšepe tse phahameng tsa carbon kapa alloy li khethoa bakeng sa bokhoni ba tsona ba ho arabela ho carburizing le ho tima, ho fana ka bobeli bo thata ba holim'a metsi le ho tiea ha mantlha.

2. Carburizing:Carburizing e arola khabone holim'a tšepe ho eketsa boima. Bakeng sa sehokelo sa ketane se nang le bophara ba 20 mm;Botebo ba Carburizing: 10% ea 20 mm = 2 mm;Boima bo Atlehileng: 5-6% ea 20 mm = 1-1.2 mm ho 550 HV;Sena se etsa sebaka se thata, se sa senyeheng ha se ntse se boloka ductile core ho monya meroalo e matla.

3. Kalafo ea Mocheso:Quenching: Ka mor'a carburizing, likarolo quenched ho notlela ka holim'a thatafala (800 HV bakeng sa liketane, 600 HV bakeng sa mahlaahlela);Ho futhumala: Ho futhumala ho laolehileng (mohlala, ho 200–250°C) ho lokisa lintho tsa mantlha, ho netefatsa ho tiea le matla a ho robeha a 280–300 N/mm². Ho halefa ho feta tekano ho fokotsa boima, athe ho halefa ho ka baka brittleness.

4. Balancing Act: Ho thatafala: Ho thatafala holimo holimo ho hanyetsa ho roala ho tloha linthong tse senyang;Matla: Matla a maholo a thibela ho robeha ha brittle tlas'a meroalo e thata.SCIC e laola botebo ba "carburizing" le liparamente tse futhumatsang ho qoba bofokoli bo feteletseng ha o ntse o kopana le litlhaloso tsa bareki.

(lihokelo tsa ketane tse nang le boima bo phahameng ba carburized surface)

(lihokelo tsa ketane tse nang le boima bo phahameng ba carburized holim'a metsi, kamora tlhahlobo ea matla)

Ts'ebetso ea rona ea tlhahiso e laoloa ka hloko ho fihlela tekano e phethahetseng pakeng tsa boima le matla. Ka carburizing e nepahetseng le kalafo ea mocheso, re etsa bonnete ba hore ronadiketane le diketaneE-ba le sebaka se thata, se sa senyeheng ha u ntse u boloka mokokotlo o thata ho sebetsana le meroalo e matla ts'ebetsong ea hau. Tekanyo ena e bohlokoa bakeng sa ho eketsa nako ea bophelo le ho tšepahala ha lisebelisoa.

III. Ho netefatsa Nako ea Bophelo ka Ts'ebetso le Tlhokomelo

Leha ho le joalodiketane le diketane tsa boleng bo hodimo, ts'ebetso e nepahetseng le tlhokomelo li bohlokoa ho eketsa nako ea bophelo ka har'a lifeme tsa samente tsa libakete. SCIC e fana ka tataiso e latelang ho bareki:

Tataiso ea Tlhokomelo

1. Litlhahlobo tsa Kamehla:Hlahlobadiketane le diketanebakeng sa matšoao a ho roala, joalo ka bolelele (mohlala,> 2–3% ea bolelele ba pele), deformation, kapa mapatso a bokaholimo. Ho lemoha kapele ho thibela ho hloleha.

2. Lubrication:Kenya mafura a mocheso o phahameng, a sebetsang ka thata ho fokotsa ho hohlana le ho senyeha. Lubricate lihora tse ling le tse ling tse 100-200 tsa ts'ebetso, ho latela maemo.

3. Tlhokomelo ea Tension:Boloka tsitsipano e nepahetseng ea ketane ho qoba ho thella ho feteletseng (ho baka ho thothomela) kapa ho tiisa ho feta tekano (moaparo o ntseng o eketseha). Fetola ho ea ka litlhaloso tsa SCIC.

4. Phetoho e nakong:Nka sebaka sa lisebelisoa tse tsofetseng kapa tse senyehileng hang-hang ho thibela ho hloleha ha cascading. Ka mohlala, shackle e holofetseng e lokela ho fetoloa hang-hang.

5. Mekhoa e metle ea ts'ebetso:Sebetsa ka har'a meeli ea moralo (mohlala, qoba ho jara ho feta 280–300 N/mm² ho fokotsa matla a matla) ho fokotsa khatello ea maikutlo.

Ho eketsa nako ea bophelo ba liketane le mahlaahlela a hau, latela mekhoa ena: hlahloba khafetsa hore na ha e senyehile hakae, etsa bonnete ba hore ho na le mafura a nepahetseng, hlokomela tsitsipano ea ketane, 'me u nke likarolo tse senyehileng hang-hang. Ka ho latela litataiso tsena le ho sebetsa ka har'a meeli ea moralo, o ka eketsa ts'epahalo le bokhoni ba li-lifti tsa hau tsa libakete.

Mohlala: Phello ea Sebele ea Lefatše

Boemo:

Feme ea samente e ne e tobane le ho hloleha khafetsa ha likhoele tse pota-potileng, ka nako ea ho theoha ha lihora tse 10 ka khoeli ka lebaka la liketane tse nang le boima ba 600 HV feela le botebo bo sa tebang ba carburizing. Sena se ile sa lebisa litšenyehelong tse phahameng tsa ho lokisa le ho lahleheloa ke tlhahiso.

Tharollo:

Feme e amohetse liketane tsa khokahanyo tse thata tsa SCIC:

- Paramethara: bophara ba 30mm, boima ba bokaholimo ba 800 HV, botebo ba 3mm ba carburizing, boima ba 1.8mm bo sebetsang ho 550 HV, 290 N/mm² matla a ho pshatla.

- Tlhokomelo: Ho hlahlojoa ha beke le beke, ho tlotsoa lihora tse ling le tse ling tse 150, le liphetoho tsa tsitsipano.

(lihokelo tsa ketane tse nang le botebo bo ntlafalitsoeng ba carburizing ho isa ho 10% ea lihokelo tsa lihokelo)

IV. Liphetho

1. Nako ea ho phomola: E fokotsoe ke 80% (ho ea ho lihora tsa 2 / khoeli).

2. Nako ea bophelo: Liketane li ile tsa nka likhoeli tse 18 (ho bapisoa le likhoeli tse 6 pele ho moo).

3. Ho Boloka Litšenyehelo: Litšenyehelo tsa tlhokomelo li theohile ka 50% selemo le selemo.

Sena se bontša kamoo likarolo tsa boleng bo holimo tsa SCIC le tataiso ea tlhokomelo li fanang ka melemo e bonahalang.

V. Qetello

1. Ho Khetha Likarolo Tse Nepahetseng:Liketane le liketane tse lumellanang le DIN tsa SCIC, e tšehetsoeng ke moralo o phahameng le taolo ea boleng, ho netefatsa ts'ireletseho le ts'ebetso e sebetsang ka har'a lisebelisoa tsa libakete tsa fektheri ea samente.

2. Ho leka-lekanya ho Thata le Matla: Mekhoa ea rona e nepahetseng ea tlhahiso e kopana le litlhaloso tsa bareki, ho fana ka khanyetso ea ho apara le matla a ho jara mojaro.

3. Ho eketsa Nako ea Bophelo: Tataiso e sebetsang ea tlhokomelo e tiisa ho tšepahala ha nako e telele.

Ka ho sebelisana le SCIC, bareki ba fumana monyetla oa ho fumana liketane le liketane tse entsoeng ka bokhabane, tse lokiselitsoeng litlhoko tsa bona, 'me li tšehetsoa ke maano a netefalitsoeng a ho ntlafatsa ts'ebetso le ho fokotsa litšenyehelo.

Nako ea poso: Apr-21-2025